Problem statement of client

Their textile manufacturing plant has more than 50 machines working with over 5000 threads of varied colours and materials. This huge mix of raw materials and orders became difficult to handle with increasing demand as there was no proper method for accountability. They could not use any normal off the shelf stock management software because of the variants associated with a textile industry.

Process

They needed a custom ERP system that would improve their manufacturing process efficiency, manage data and stock centrally and organise the entire end-to-end operations. Our ERP developers used the below 3 step methodology to achieve their goals:

01

Research

Research

Our team visits their manufacturing plant to understand the entire workflow, raw materials and finished goods. This helped to understand the complexity of the project and think of ideas and solutions accordingly.

02

Mock-ups

Mock-ups

After understanding how all the departments and intra-departments function, our enterprise application development team were able to fixate on and create mock-ups of a few design layouts.

03

Development and Launch

Development and Launch

A custom ERP system was designed and built which incorporated excellent features particularly needed in the textile industry. This software could be used for multiple functions including thread management, stock management, client database management, and sales management.

Solution

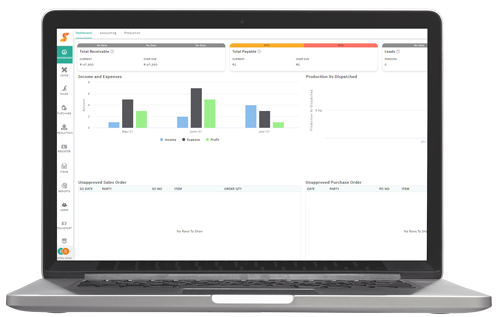

This resource planning system was developed after a detailed study on the client’s requirements to improvise their manufacturing efficiency and reduce manual work. Here is a glimpse of the solutions we provided through this custom ERP solution:

Result

Efficiency

They were able to improve their manufacturing efficiency by 25%.

dead Inventory

They can now identify dead inventory, plan to get rid of it sooner to get rotational cash flow.

They are able to view all business operations from a single dashboard, foresee sales orders and make strategic decisions without investing extra time and efforts.

There were zero errors in manufacturing due to elaborate reporting and easier thread recipe and design methods in the ERP system.